Cluster Recognition

This feature is to enable customer in reducing the number of tool hits to reduce the deflection when punching is performed. If the user wants to use this option, he or she can select the appropriate cluster tools from the cluster tool database. In order to make the cluster tool recognition works as desired, a user needs to consider the parameter of the cluster tool, and then consider the perforated pattern type as well as the gap between the holes.

The cluster recognition algorithm is only valid with square and angle perforated pattern type where the holes type is round. The reason is because the actual/common clustering tools that available in the commercial market are limited to square and staggered cluster pattern. By implementing cluster recognition, the total tool hits can be reduced. Thus, this will make the perforating faster and cheaper.

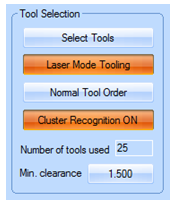

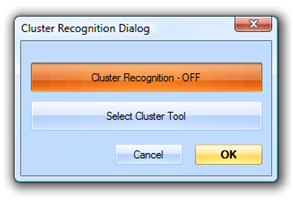

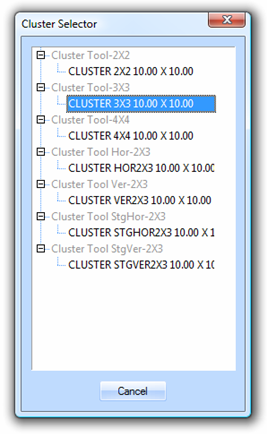

In order to activate the cluster tool recognition, user needs to select a particular cluster tool from available cluster tool database by clicking the cluster recognition button (i.e. the fourth button on the Tool Selection group). When it is clicked a cluster tool dialog box will be opened and there are two buttons to let the user decided either to activate the cluster recognition or not. When the first button is clicked, this will deactivated the tool recognition. However, when the second button is clicked, another dialog will be opened to let he customer to choose the suitable cluster recognition tool to be used for their perforated pattern design.

When the Cluster Recognition button is clicked, it will open the Cluster Recognition Dialog box where user can enable and disable this feature. In this dialog box, user can also select the predefined cluster tool to be used for the recognition.

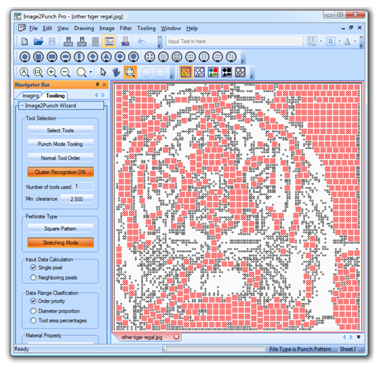

Illustrations below is to show how the cluster recognition can be performed on a perforated pattern design by using a cluster tool of 3X3 to eliminate some tool hits that has been generated by a round tool of 6mm diameter. Without cluster recognition, the total toolhit will be 9435 times. However, after applying the cluster recognition tool, the total tool hits are reduced to only 4211 times.

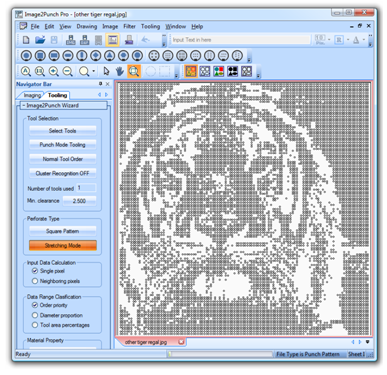

This illustration below shows the perforated pattern generated by a single tool hits and constructed from 9435 hits.

This shows the perforated pattern generated by single tool hits where the cluster recognition is applied to the final calculation and the total tool hit is becoming to only 4211 time. The black patterns are represented the single tool hits and the red patterns are represented the cluster tool that has been used to replace the single tool hits.